Water Cooled Spindle Fluid

Thermal conductivity water 0 67.

Water cooled spindle fluid. The cooling effect will be good because the temperature usually tested will not exceed 40 degrees after the water has been circulated. All you truly need for a water cooling loop is distilled water and a biocide. This is the core foundation of your coolant which can handle your chosen dye should you desire a colored finish. I use a really simple setup a 5 gallon bucket 9 flojet water pump from electronic goldmine and 2 gallons of prestone antifreeze.

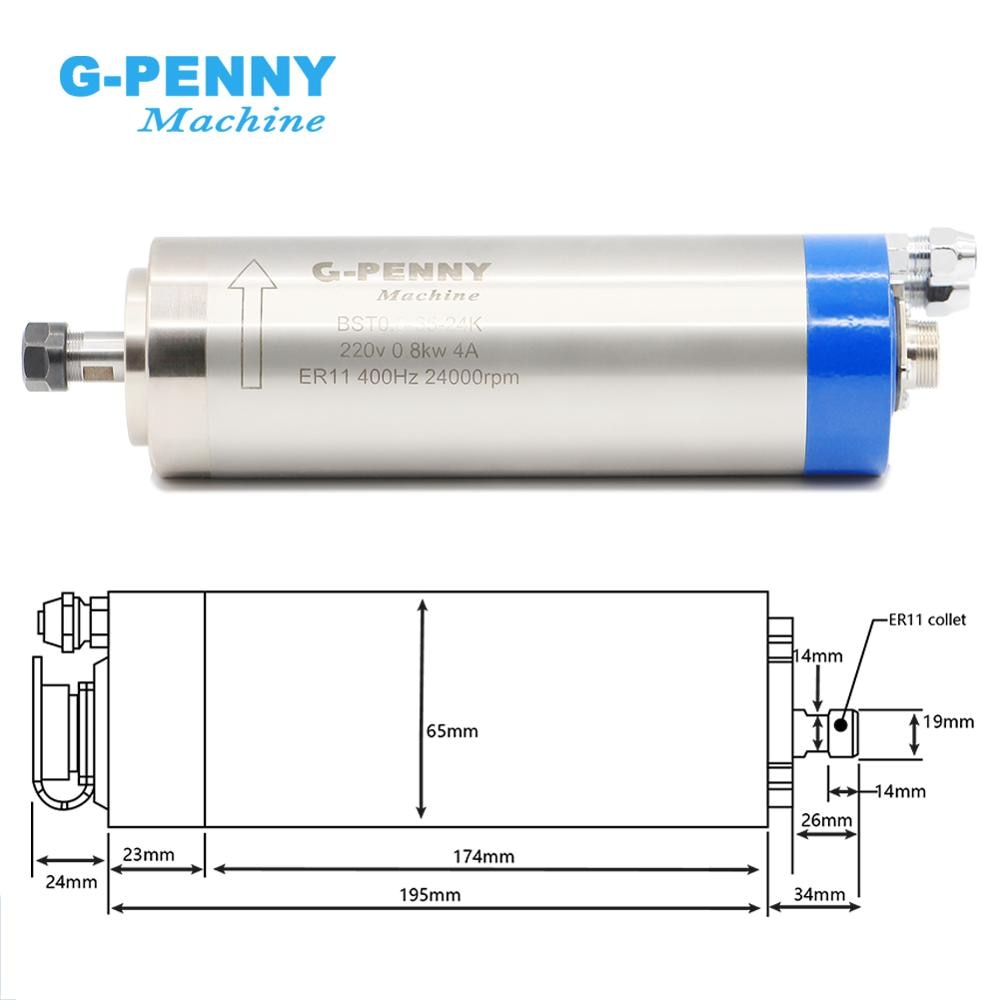

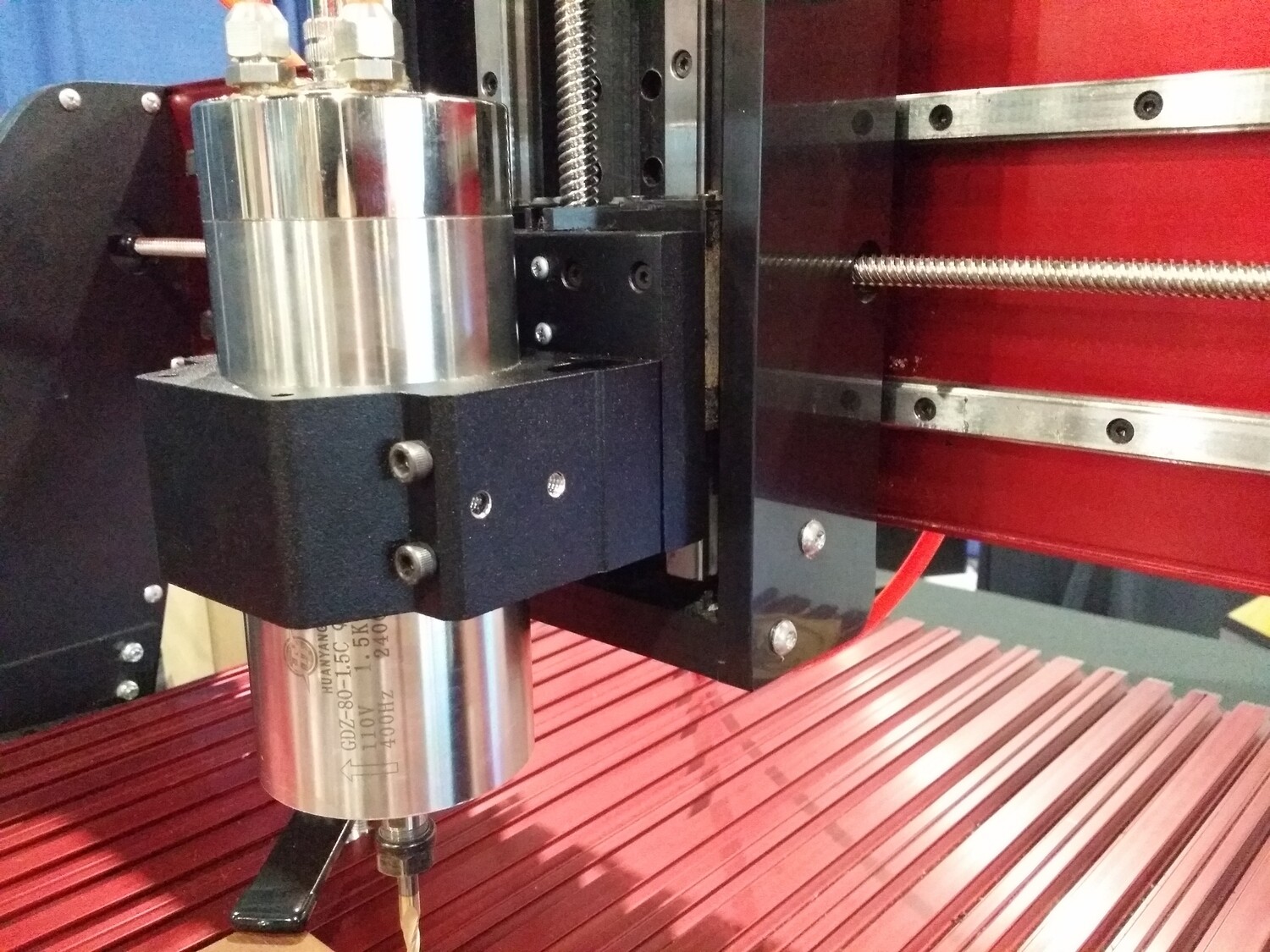

They are usually designed to resist rust and odours. Water cooling spindle is using water circulation to cool the heat generated by the spindle rotating with high speed 18 000 or 24 000 rpm. The air cooled spindles have a force of air that partly makes the vacuum and dust shoe non effective unless we design a diverter which limits the cooling effect for the spindle. These oils mix at anywhere from 20 1 to 50 1 with water.

107658 motorex cool x is a ready to use cooling fluid for high precision spindles with excellent corrosion protection. While the air cooled spindle is cooled by a fan and the cooling effect is definitely not as good as that of water cooling. We like the water cooled spindles since they don t blow the chips around the shop. Cool core ready is used as coolant and an anti corrosion agent in motor spindle cooling systems in particular where there is an inadequate supply of clean drinking water available for mixing purposes.

Water is the best liquid for carrying heat away from the spindle assuming the spindle does not get hotter than the boiling point of water at your particular elevation.