Water Baffles Molds

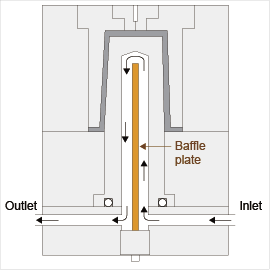

Plastic baffles have built in ribs that create turbulent flow and reduce stagnant laminar flow.

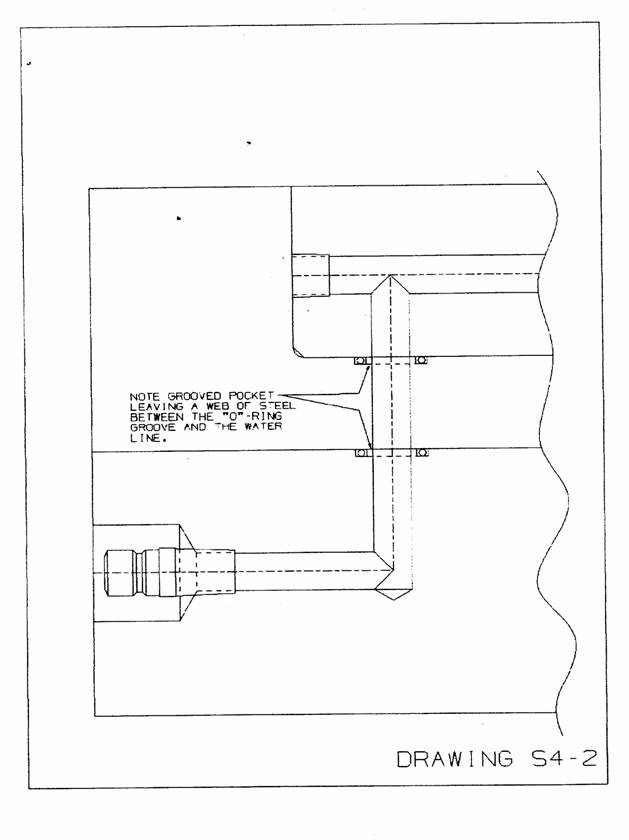

Water baffles molds. Pcs company is a leading supplier providing quality mold bases mold base components molding supplies and hot runner products for the plastics and die cast industries. Exact tolerances for improved flow performance. In such molds where the water channels can t be drilled close to the part surface baffles can be inserted into a channel perpendicular to the main water channel. Cooling channels are typically drilled through the mold cavity and core.

Parallel cooling is ideal for baffles and fountains. You have 0 items in your cart. This is what s called parallel cooling. United states 800 626 6653 canada 800 387 6600 europe 32 15 215011 asia 86 755 8601 9031.

Almost all toolmakers cool molds the same way with drilled cooling channels. The units feature patented side wipers that prevent coolant blow by thus ensuring coolant flow to the end of the baffles. Our global customers include plastic injection molders mold makers mold designers and die casters. Brass baffle blades tend to be about 0 095 thick with about 0 020 clearance on each side to allow the blade to be screwed into the threaded tap at the end of the drilled cooling channel.

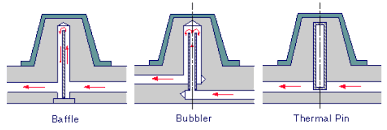

Water cooler bubbler and baffle are sections of cooling lines that divert the coolant flow into areas that would normally lack cooling. The mold however may consist of areas too far away to accommodate regular cooling channels. All cavities would present the same uniform resistance and all would ideally have the same cooling. Dependable brazed solid brass construction.

The product is effective in improving cooling of targeted hot spots and dramatically improves cooling time. Turbulent flow plastic baffles provide superior mold cooling performance versus traditional brass baffles. A leak free seal up to 600 p s i. The best way to get the heat out of the deep draw sections of the mold is with baffle blades.

The inlet to the cavity farthest from the molds inlet would have the greatest resistance yet the outlet from its corresponding cavity would have the least.