Water Jet Cutting Stone Uk

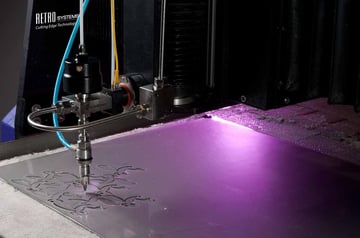

As a cutting tool instead of a tool a powerful jet of water or a mixture of water and ab.

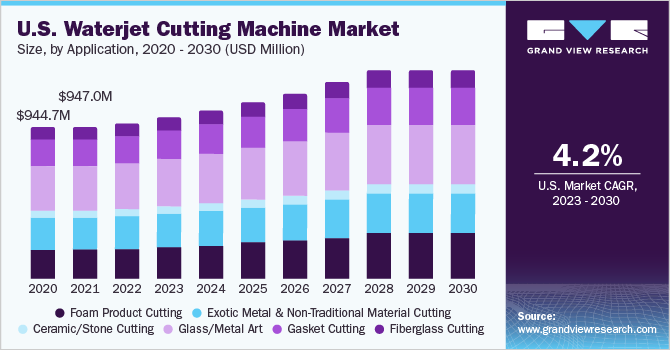

Water jet cutting stone uk. Ceramic and stone cutting water jet uk ceramic and stone cutting water jet cutting is the best and easiest way to profile cut ceramic granite tiles slabs limestone and marble. Enter thickness of material. Stoneworx have invested in the latest cutting edge excuse the pun to ensure that we can provide the most creative and imaginative design solutions for your stone investment. Flow is the inventor and world leader in waterjet cutting solutions.

Hydro abrasive technology water jet cutting with stone and metal. From shopping centres to domestic installations wjuk can cover all applications. We have the ability to cut taper free parts angles from 0 to 60 even complex shapes in tube and pipe it is so versatile there are no limitations. We offer metal cutting glass cutting tile cutting marble cutting ceramic cutting stone cutting and more.

Ceramics porcelain stone marble hardwood softwood plywood acrylic glass bulletproof glass paper plastics rubber foam carbon fibre composites concrete slate zirconia graphite steel titanium aluminium copper brass alloys other other. Precision waterjets in stoke cancut through most materials such as metals plasitcs ceramics stone and much more. We use cookies to create the most secure and effective website possible for our customers. Extremely efficient and cost effective.

100 separation cut 80 rough cut 60 standard cut 40 quality cut 20 excellent cut choose what material you want to cut. Waterjet cutting is a flexible and precise cutting method and the process allows you to cut almost any material. Water jet stone cutting of all natural and man made stones is simple fast and highly effective. Primus is a range of water jet cutting machines designed to meet the needs of companies searching for the maximum versatility.

It offers the possibility to process a wide selection of materials from stone to metal from glass to plastic from ceramic to compound materials. The cutting process makes use of waterjet technology which machines materials by means of a high speed jet of water and abrasive where necessary with pressures that can reach 400 mpa. If you can imagine a design and draw it we can cut it and turn it into a reality.