Water In Hydraulic Oil Symptoms

The saturation level is the amount of water that can dissolve in the oil s molecular chemistry and is typically 200 to 300 ppm at 68 f 20 c for mineral hydraulic oil.

Water in hydraulic oil symptoms. Both these issues can cause component or system damage with extreme cases of cavitation being known to cause metal erosion and failure of system components. Aeration accelerates degradation of the fluid and causes damage to system components through loss of lubrication overheating and burning of seals. The level of dissolved water needs to be kept as low as possible always follow fluid supplier guidelines to avoid cooler fluid e g. As oil is lighter than water any water will collect at the bottom of the pan with the oil floating on top.

Turn the engine off and let the vehicle sit for a few hours. This is an indication of coolant in the oil being burned off. Skf state that hydraulic oil containing just 0 1 water by volume cuts bearing life in half while. Note that if hydraulic oil is cloudy it indicates that a minimum of 200 300 ppm of water is present.

This in turn causes circuit pressure to fall below the level of vapour in the hydraulic fluid. Water in hydraulic oil has a number of negative effects. Oil becomes cloudy when it is contaminated with water above its saturation level. Air usually enters the hydraulic system through the pump s inlet.

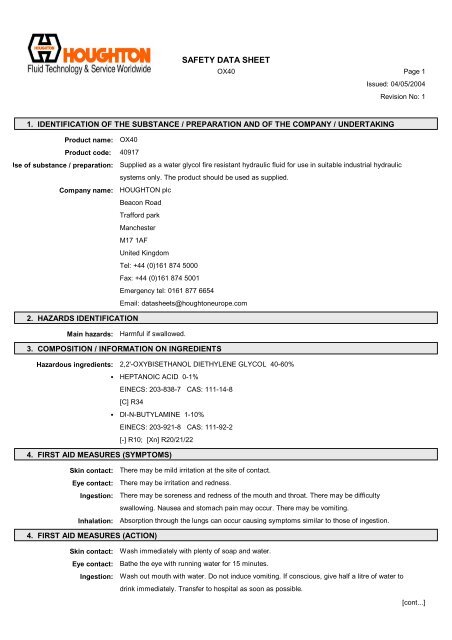

The saturation level is the amount of water that can dissolve in the oil s molecular chemistry and is typically 200 to 300 ppm at 20 c for mineral hydraulic oil. Oil becomes cloudy when it s contaminated with water above its saturation level. There are a number of potentially detrimental effects commonly associated with any amount of water in hydraulic oil including surface corrosion and the accelerated fatigue of metal components. 2 things cause milky water oil first being cracked shifter boot and 2nd being plugged trans breather.

Damper clutch at flywheel slippage can cause weak hyd s by letting pump slow down. Depletes some additives and reacts with others to form corrosive by products which attack some metals. Remove the drain plug from the oil pan with a wrench draining a small amount of oil into a drain pan. In the reservoir to shed fee water due to the.

It should be around 165 psi. Reduces lubricating film strength which leaves critical surfaces vulnerable to wear and corrosion. Free water needs to be avoided and removed if present. If you have worked with hydraulic equipment for any length of time it s likely that you ve come across a hydraulic system with cloudy oil.

The knocking sound that comes from this is caused as the vapour cavities implode during compression. Oil becomes cloudy when it s contaminated with water above its saturation level. Either form of water is harmful to both the fluid and the hydraulic system itself. Other symptoms include foaming of the fluid and erratic actuator movement.

Reduces filterability and clogs filters.