Water Based Screen Printing Ink Formulation

Offset ink manufacturing process gravure ink formulation uv ink formulation raw materials used to make ink ink thinner ingredients ink reducer formula water based gravure ink siegwerk.

Water based screen printing ink formulation. Water based screen printing inks. From ready for use rfu inks to newer formulations like high solid acrylic hsa inks. Standard test methods for adhesion rub resistance and gloss were done on the printed polyethylene films. Environmentally friendly water based silver pastes adapted for screen printing were formulated with different silver contents 67 75.

I am looking for expert in chemicals formulation of water base screen printing ink who can help me to create a better water base inks. But there are a few different varieties of water based ink that make up the full list. These co solvents typically are voc s. Inks were formulated with a mixture of spherical and flake shape silver particles with 2 4 μm mean diameter.

Quantitative methods for the assessment and evaluation of the three print properties were developed. This is the process of using a discharge base which pulls the dye out creating a soft underlay and then printing plastisol or fashion based ink on top. These pastes allowed screen printing onto low temperature co fired ceramic ltcc of narrow conductive tracks with a 60 μm line width and a 3 10 8 ω m electrical resistivity. Depending on their chemical make up emulsion polymers impart ink hardness or flexibility after drying water resistance and gloss.

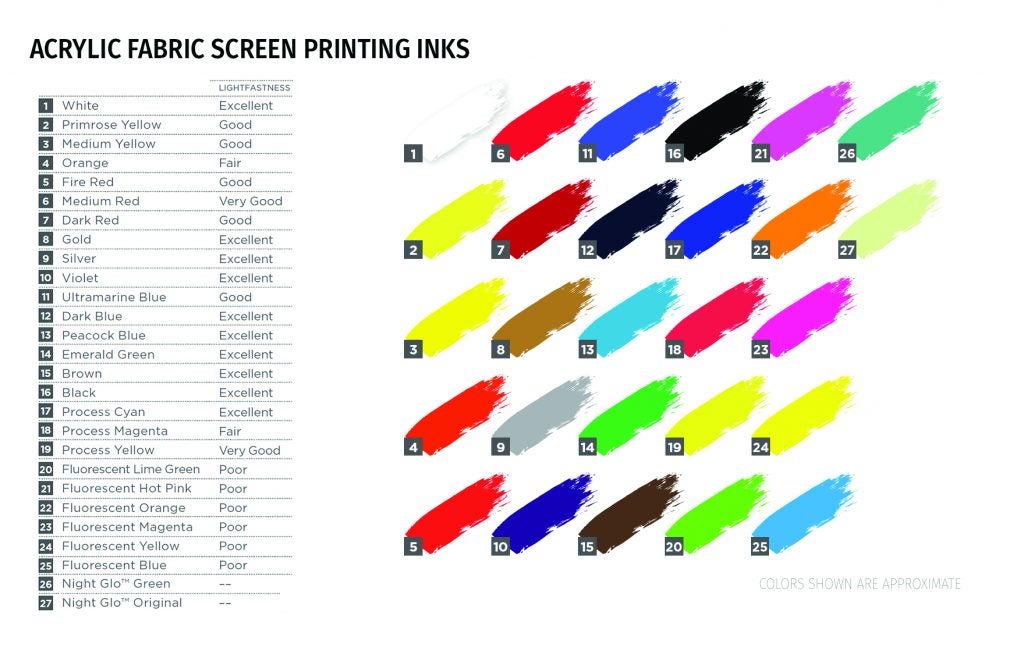

The simple answer is that water based ink is any ink which uses water as a solvent base to carry the pigment. The cms pigments afford screen printers the ability to mix any color including the pantone color range as needed with just 14 basic pigment colors. Ryonet is proud to offer environmentally friendly green galaxy water based ink. All though the main solvent in water based inks is water there can also be other co solvents present.

These inks have a super soft hand which makes them perfect for a wide variety of printing applications including shirts towels sweatpants and paper. Here s an overview of the wide ar. The ingredient selection for a typical pigment ink formulation for ink jet digital textile printing includes 5. So a 50 50 tee would only show roughly 50 opacity since the polyester won t hold water based screen printing ink.

Both types of resins solution and emulsion resins are. 3 water based inks have been in existence since around 2500 b c. Chemical engineering print textile engineering see more. A pigment dispersion for color a polymeric binder a solution polymer or latex for image durability water for aqueous inkjet inks a medium to carry other components.

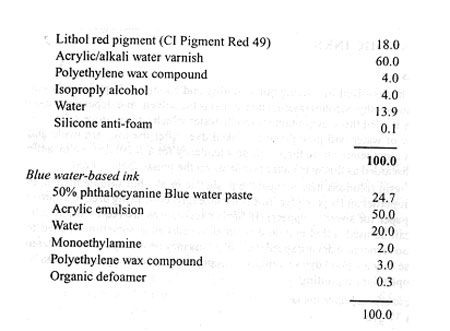

Water based systems wter based sstems printing ink additives defoamers 3d 3d polysiloxane e aqueous emulsion defoamers surface active agents surfactants especially emulsifi ers wetting and dispersing agents are used to emulsify and stabilize hydrophobic substances e g. Water based ink formulations containing wax surfactant and defoamer additives were prepared and printed on polyethylene film substrates.