Water Atomizing Spray Nozzle Droplet Size

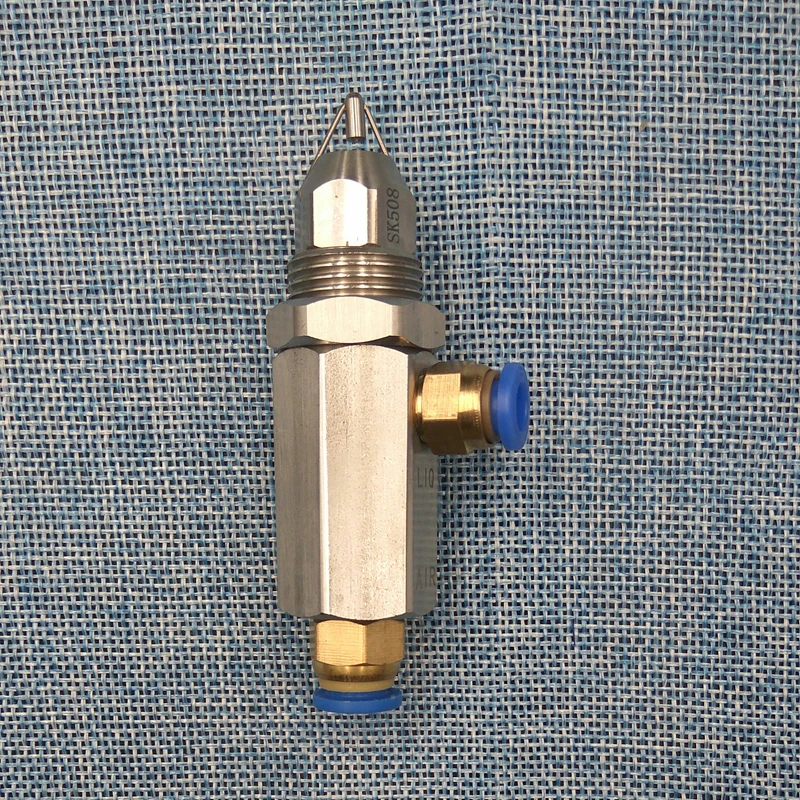

2 model eb1030ss atomizing nozzles are used to give a final sanitary rinse prior to labeling wine bottles.

Water atomizing spray nozzle droplet size. Sg specific gravity of the fluid. Fluids with higher viscosities than water will have higher mean droplet sizes for any given flow rate and pressure. Some pesticide labels specify a recommended droplet size. In practice a nozzle produces droplets from a compact flow of fluid within a specific size range.

As specific gravity is often very close to 1 and the exponent is 0 3 the effect of this is generally very small. Nozzles with droplet sizes of 60 microns to 200 microns are good for washing and applying lubricants. A vmd dv0 5 of 400 for example indicates that half of the volume is in droplet sizes smaller than 400 microns and half the volume is in droplet sizes larger than 400 microns. Variable air atomizing nozzles provide independent control of liquid atomizing air and fan air pressure for fine tuning of flow rate drop size spray distribution and coverage.

The atmosphere provides resistance and tends to break up the stream of fluid. For technical drawings and 3 d models click on a part number. In a water spray system the droplet size plays a major role. For reference a large raindrop is around 6 000 microns 0 236 in diameter.

Use nozzles producing a coarse vmd of 400 or greater droplet category. Nozzles with droplet sizes of 20 microns to 60 microns are good for moisturizing coating evaporative cooling and dust suppression. Air atomizing nozzles produce the smallest drop sizes 10 micron followed by hydraulic fine spray hollow cone flat fan and full cone nozzles. This resistance tends to overcome in part the fluid s properties of surface tension viscosity and density.

An example would be. Use of two fluid nozzles. Viscosity and surface tension. Benefits of fine droplet size include even coating and liquid conservation.

Options include clean out and or shut off needles hundreds of capacities and anti bearding air caps that resist build up around the nozzle orifice. The probability of impaction also increases as the size of the water spray droplets decreases because as the size of the droplets decreases the number of droplets increases rocha 2005. Mounting brackets are available model 901318 for 1 4 npt and model 901556 for 1 2 npt atomizing nozzles. The particle and water droplet sizes should be roughly equivalent for optimal agglomeration.

D w the droplet size for water for that particular nozzle. For more informal1on about droplet size and spray angle seepa ge84. Further it is important to be familiar with the various diameter related terms. Regarding orifice diameter the general rule is that the larger the diameter or size of the atomizer orifice the larger the average droplet size in a spray.

Since it is impractical to list all produced sizes the droplet size in µm normally is specified as d32 sauter diameter.